| Revision as of 06:24, 25 June 2008 view sourceSenator Palpatine (talk | contribs)4,929 editsm Undid revision 221599649 by 85.224.131.98 (talk)← Previous edit | Latest revision as of 08:57, 23 January 2025 view source Polyamorph (talk | contribs)Extended confirmed users, Page movers, Pending changes reviewers, Rollbackers29,989 edits →See also: MOS:NOTSEEALSO links are already present in the articleTag: Manual revert | ||

| Line 1: | Line 1: | ||

| {{ |

{{Short description|Transparent non-crystalline solid material}} | ||

| {{About|the material}} | |||

| ], a natural glass formed by ] impact, from ], ]]] | |||

| {{Pp-vandalism|small=yes}} | |||

| {{Good article}} | |||

| {{Use dmy dates|date=March 2020}} | |||

| {{Use British English|date=March 2020}} | |||

| ] | |||

| '''Glass''' is an ] (]) solid. Because it is often ] and chemically inert, glass has found widespread practical, technological, and decorative use in ] panes, ], and ]. Some common objects made of glass are named after the material, e.g., a ] for drinking, "]" for vision correction, and a "]". | |||

| ]]] | |||

| Glass is most often formed by rapid cooling (]) of the ] form. Some glasses such as ] are naturally occurring, and ] has been used to make arrowheads and knives since the ]. Archaeological evidence suggests glassmaking dates back to at least 3600 BC in ], ], or ]. The earliest known glass objects were ], perhaps created accidentally during ] or the production of ], which is a form of pottery using lead glazes. | |||

| '''Glass''' in the ''common'' sense refers to a ], ], ] ], such as that used for ]s, many ], or ], including ], ], ], ], ] (Muscovy-glass), or ]. | |||

| Due to its ease of ] into any shape, glass has been traditionally used for vessels, such as ], ]s, ]s, jars and drinking glasses. ], containing around 70% ], accounts for around 90% of modern manufactured glass. Glass can be coloured by adding metal salts or painted and printed with ]s, leading to its use in ] windows and other ] objects. | |||

| In the ''technical'' sense, glass is an inorganic product of fusion which has been cooled to a rigid condition without crystallizing.<ref>] definition of glass from 1945; also: ] 1259, Glas - Begriffe für Glasarten und Glasgruppen, September 1986</ref><ref name=Zallen83>Zallen, ''The Physics of Amorphous Solids'', John Wiley, New York, (1983).</ref><ref>''The physics of structurally disordered matter: an introduction'', Adam Hilger in association with the University of Sussex press (1987)</ref><ref name=Elliot84>Elliot, ''Physics of amorphous materials'', Longman group ltd (1984)</ref><ref>Horst Scholze: "Glass - Nature, Structure, and Properties"; Springer, 1991, ISBN 0-387-97396-6</ref> Many glasses contain ] as their main component and ''glass former''.<ref name=vogel>Werner Vogel: "Glass Chemistry"; Springer-Verlag Berlin and Heidelberg GmbH & Co. K; 2nd revised edition (November 1994), ISBN 3540575723</ref> | |||

| The ], ] and ] properties of glass make glass suitable for manufacturing ], ]s, and ] materials. Extruded ] have applications as ] in communications networks, thermal insulating material when matted as ] to trap air, or in glass-fibre reinforced plastic (]). | |||

| In the ''scientific'' sense the term glass is often extended to all ]s (and melts that easily form amorphous solids), including ]s, ]s, or other silica-free amorphous solids. In addition, besides traditional ] techniques, any other means of preparation are considered, such as ], and the ] method.<ref name=vogel/> However, '']'' commonly includes only ] amorphous solids, while plastics and similar organics are covered by ], ] and further scientific disciplines. | |||

| == Microscopic structure == | |||

| The optical and physical properties of glass make it suitable for applications such as ], ], ] and ] material, ], thermal insulator (]), reinforcement fiber (], ]), and ]. | |||

| ] in two dimensions. No long-range order is present, although there is local ordering to the ] arrangement of oxygen (O) atoms around the silicon (Si) atoms.|alt=A graphic showing the lack of periodic arrangement in the microscopic structure of glass]] | |||

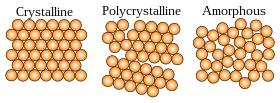

| ] has atoms in a near-perfect ] arrangement; a ] is composed of many microscopic crystals; and an ] solid such as glass has no periodic arrangement even microscopically.|alt=A graphic visually showing the difference between the microscopic arrangement of single crystals, polycrystals, and amorphous solids, as explained in the caption]] | |||

| {{Main|Structure of liquids and glasses}} | |||

| The standard definition of a ''glass'' (or vitreous solid) is a non-crystalline solid formed by rapid melt ].<ref>] definition of glass from 1945</ref><ref name="Zallen83">{{cite book |last=Zallen |first=R. |title=The Physics of Amorphous Solids |publisher=John Wiley |place=New York |year=1983 |pages=1–32|isbn=978-0-471-01968-8}}</ref><ref name="Cusack87">{{Cite book |last=Cusack |first=N.E. |title=The physics of structurally disordered matter: an introduction |publisher=Adam Hilger in association with the University of Sussex press |year=1987 |page=13 |isbn=978-0-85274-829-9}}</ref><ref name="Horst Scholze 1991">{{Cite book |last=Scholze |first=Horst |title=Glass – Nature, Structure, and Properties |publisher=Springer |year=1991 |pages=3–5 |isbn=978-0-387-97396-8}}</ref> However, the term "glass" is often defined in a broader sense, to describe any non-crystalline (]) solid that exhibits a ] when heated towards the liquid state.<ref name="Horst Scholze 1991" /><ref name="Elliot84">{{Cite book |last=Elliot |first=S.R. |title=Physics of Amorphous Materials |publisher=Longman group ltd |year=1984 |pages=1–52 |isbn=0-582-44636-8}}</ref> | |||

| Glass is an ]. Although the atomic-scale structure of glass shares characteristics of the structure of a ], glass exhibits all the mechanical properties of a solid.<ref>{{cite web|last=Neumann |first=Florin |url=http://dwb.unl.edu/Teacher/NSF/C01/C01Links/www.ualberta.ca/~bderksen/florin.html |title=Glass: Liquid or Solid – Science vs. an Urban Legend |access-date=8 April 2007 |url-status=dead |archive-url=https://web.archive.org/web/20070409022023/http://dwb.unl.edu/Teacher/NSF/C01/C01Links/www.ualberta.ca/~bderksen/florin.html |archive-date=9 April 2007}}</ref><ref name="Gibbs">{{cite web |last=Gibbs |first=Philip |url=http://math.ucr.edu/home/baez/physics/General/Glass/glass.html |title=Is glass liquid or solid? |access-date=21 March 2007 |url-status=live |archive-url=https://web.archive.org/web/20070329154027/http://math.ucr.edu/home/baez/physics/General/Glass/glass.html |archive-date=29 March 2007}}</ref><ref>"Philip Gibbs" ''Glass Worldwide'', (May/June 2007), pp. 14–18</ref> As in other ]s, the atomic structure of a glass lacks the long-range periodicity observed in ]. Due to ] constraints, glasses do possess a high degree of short-range order with respect to local atomic ].<ref>{{cite journal |last=Salmon |first=P.S. |title=Order within disorder |doi=10.1038/nmat737 |journal=Nature Materials |pmid=12618817 |volume=1 |issue=2 |year=2002 |pages=87–8|s2cid=39062607 |issn = 1476-1122 }}</ref> The notion that glass flows to an appreciable extent over extended periods well below the glass transition temperature is not supported by empirical research or theoretical analysis (see ]). Though atomic motion at glass surfaces can be observed,<ref>{{cite journal |last1=Ashtekar |first1=Sumit |last2=Scott |first2=Gregory |last3=Lyding |first3=Joseph |last4=Gruebele |first4=Martin |year=2010 |title=Direct Visualization of Two-State Dynamics on Metallic Glass Surfaces Well Below Tg |journal=J. Phys. Chem. Lett. |volume=1 |issue=13 |pages=1941–1945 |doi=10.1021/jz100633d |arxiv=1006.1684 |s2cid=93171134 }}</ref> and viscosity on the order of 10<sup>17</sup>–10<sup>18</sup> Pa s can be measured in glass, such a high value reinforces the fact that glass would not change shape appreciably over even large periods of time.<ref name=Elliot84 /><ref>{{cite journal |last1=Vannoni |first1=M. |last2=Sordini |first2=A. |last3=Molesini |first3=G. |year=2011 |title=Relaxation time and viscosity of fused silica glass at room temperature |journal=Eur. Phys. J. E |volume=34 |issue=9 |pages=9–14 |doi=10.1140/epje/i2011-11092-9|pmid=21947892 |s2cid=2246471 }}</ref> | |||

| == General properties, uses, occurrence == | |||

| ] made from ] (])]] | |||

| === Formation from a supercooled liquid === | |||

| ], using thin sheets of special ]-free<ref>See article: ], TFT-LCD Glass substrates</ref> glass]] | |||

| {{Main|Glass transition|Glass formation}} | |||

| {{Unsolved |physics |What is the nature of the ] between a fluid or regular solid and a glassy phase? | |||

| "The deepest and most interesting unsolved problem in solid state theory is probably the theory of the nature of glass and the glass transition." —]<ref>{{cite journal |last=Anderson |first=P.W. |journal=Science |volume=267 |year=1995 |doi=10.1126/science.267.5204.1615-e |pmid=17808155 |issue=5204 |pages=1615–16 |title=Through the Glass Lightly|s2cid=28052338 }}</ref> }} | |||

| For melt quenching, if the cooling is sufficiently rapid (relative to the characteristic ] time) then crystallization is prevented and instead, the disordered atomic configuration of the ] liquid is frozen into the solid state at T<sub>g</sub>. The tendency for a material to form a glass while quenched is called glass-forming ability. This ability can be predicted by the ].<ref name="phillips1979">{{cite journal |last=Phillips |first=J.C. |title=Topology of covalent non-crystalline solids I: Short-range order in chalcogenide alloys |journal=Journal of Non-Crystalline Solids |year=1979 |volume=34 |issue=2 |page=153 |doi=10.1016/0022-3093(79)90033-4 |bibcode=1979JNCS...34..153P }}</ref> Generally, a glass exists in a structurally ] state with respect to its ] form, although in certain circumstances, for example in ] polymers, there is no crystalline analogue of the amorphous phase.<ref name="Folmer">{{cite journal |last1=Folmer |first1=J.C.W. |last2=Franzen |first2=Stefan |title=Study of polymer glasses by modulated differential scanning calorimetry in the undergraduate physical chemistry laboratory |journal=Journal of Chemical Education |year=2003 |volume=80 |issue=7 |page=813 |doi=10.1021/ed080p813 |bibcode=2003JChEd..80..813F}}</ref> | |||

| Glass is sometimes considered to be a liquid due to its lack of a first-order ]<ref name=Gibbs /><ref>{{cite web|last=Loy |first=Jim |url=http://www.jimloy.com/physics/glass.htm |title=Glass Is A Liquid? |access-date=21 March 2007 |url-status=dead |archive-url=https://web.archive.org/web/20070314004114/http://www.jimloy.com/physics/glass.htm |archive-date=14 March 2007}}</ref> | |||

| Ordinary glass is prevalent due to its transparency to ]. This transparency is due to an absence of electronic ]s in the range of visible light. The ] of the glass on length scales greater than the ] of visible light also contributes to its transparency as heterogeneities would cause light to be ], breaking up any coherent image transmission. Many household objects are made of glass. ], ] and ] are often made of glass, as are ]s, ]s, ], ], computer ]s, and ]s. | |||

| where certain ] ] such as ], ] and ] are discontinuous through the glass transition range. The ] may be described as analogous to a second-order phase transition where the intensive thermodynamic variables such as the ] and ] are discontinuous.<ref name=Zallen83 /> However, the equilibrium theory of phase transformations does not hold for glass, and hence the glass transition cannot be classed as one of the classical equilibrium phase transformations in solids.<ref name="Horst Scholze 1991" /><ref name="Elliot84" /> | |||

| == Occurrence in nature == | |||

| In research ], ], ]s, and other ] are often made of ] for its low ], giving greater resistance to ] and greater accuracy in measurements. For high-temperature applications, ] is used, although it is very difficult to work. Most ] is ], but large laboratories also keep a ] on staff for preparing custom made glass equipment. | |||

| {{Main|Volcanic glass|Impactite|Fulgurite}} | |||

| Glass can form naturally from volcanic magma. ] is a common volcanic glass with high silica (SiO<sub>2</sub>) content formed when felsic lava extruded from a volcano cools rapidly.<ref>{{cite web|url=https://geology.com/rocks/obsidian.shtml|title=Obsidian: Igneous Rock – Pictures, Uses, Properties|website=geology.com}}</ref> ] is a form of glass formed by the impact of a ], where ] (found in central and eastern Europe), and ] (found in areas in the eastern ], the ] and ]) are notable examples.<ref>{{cite web|url=https://geology.com/meteorites/impactites.shtml|title=Impactites: Impact Breccia, Tektites, Moldavites, Shattercones|website=geology.com}}</ref> ] of ] can also occur when ] strikes ], forming hollow, ] structures called ]s.<ref>{{Cite book|url=https://books.google.com/books?id=cxEEAAAAQAAJ&pg=PA363|title=Land, sea and sky; or, Wonders of life and nature, tr. from the Germ. of H.J. Klein and dr. Thomé, by J. Minshull|last=Klein|first=Hermann Joseph|date=1881-01-01}}</ref> ] is a glassy residue formed from the desert floor sand at the ] ] site.<ref>{{Cite news|url=http://www.atlasobscura.com/articles/trinitite-trinity-test-mineral-cultural-jewelry|title=The Long, Weird Half-Life of Trinitite|last=Giaimo|first=Cara|date=2017-06-30|work=Atlas Obscura|access-date=2017-07-08|language=en|df=mdy-all}}</ref> ], found in ], is proposed to originate from ] grassland fires, ] strikes, or ] by one or several ]s or ]s.<ref>{{cite journal|last1=Roperch |first1=Pierrick |last2=Gattacceca |first2=Jérôme |last3=Valenzuela |first3=Millarca |last4=Devouard |first4=Bertrand |last5=Lorand |first5=Jean-Pierre |last6=Arriagada |first6=Cesar |last7=Rochette |first7=Pierre |last8=Latorre |first8=Claudio |last9=Beck |first9=Pierre |title=Surface vitrification caused by natural fires in Late Pleistocene wetlands of the Atacama Desert|journal=Earth and Planetary Science Letters |volume=469 |issue=1 July 2017 |pages=15–26 |date=2017 |doi=10.1016/j.epsl.2017.04.009|bibcode=2017E&PSL.469...15R |s2cid=55581133 |url=https://hal.archives-ouvertes.fr/hal-02889687 }}</ref> | |||

| Sometimes, glass is created naturally from volcanic ], ] strikes, or ] impacts (e.g., ], ], ], ], ]). If the lava is ] this glass is called ], and is usually black with impurities. Obsidian is a raw material for ]s, who have used it to make extremely sharp ] since the ]. | |||

| <gallery mode="nolines"> | |||

| Glass sometimes occurs in nature resulting from human activity, for example ] (from nuclear testing) and ]. | |||

| File:Lipari-Obsidienne (5).jpg|A piece of volcanic ] glass | |||

| ===Glass in buildings=== | |||

| File:Moldavite Besednice.jpg|], a natural glass formed by ] impact, from ], ] | |||

| {{main|Architectural Glass|Glazing in architecture|Window}} | |||

| File:Fulgurites-algeria.jpg|Tube ] | |||

| File:Trinitite from Trinity Site.jpg|], a glass made by the ] | |||

| File:Libyan Desert Glass.jpg|] | |||

| </gallery> | |||

| == History == | |||

| ] sheets in apartments in ], ].]] | |||

| {{Main|History of glass}} | |||

| ] from the 4th century|alt=Refer to caption]] | |||

| Naturally occurring ] glass was used by ] societies as it fractures along very sharp edges, making it ideal for cutting tools and weapons.<ref name="Harvey09">{{Cite book|url=https://books.google.com/books?id=7ig5XnOx4RMC&pg=PA83|pages=83–90|title=Fundamental Building Materials|last=Ward-Harvey|first=K.|date=2009|publisher=Universal-Publishers|isbn=978-1-59942-954-0}}</ref><ref>{{cite web |url=https://www.nationalgeographic.com/news/2015/04/150413-Paleolithic-obsidian-weapons-arteni-armenia-archaeology/ |archive-url=https://web.archive.org/web/20191003025824/https://www.nationalgeographic.com/news/2015/04/150413-Paleolithic-obsidian-weapons-arteni-armenia-archaeology/ |url-status=dead |archive-date=3 October 2019 |title=Digs Reveal Stone-Age Weapons Industry With Staggering Output |date=13 April 2015 |website=National Geographic News}}</ref> | |||

| Glassmaking dates back at least 6000 years, long before humans had discovered how to ] iron.<ref name="Harvey09" /> Archaeological evidence suggests that the first true synthetic glass was made in ] and the coastal north ], ] or ].<ref name="Henderson_ancient_glass">{{cite book |author=Julian Henderson |title=Ancient Glass |year=2013 |publisher=Cambridge University Press |doi=10.1017/CBO9781139021883.006 |pages=127–157}}</ref><ref>{{cite web |url=http://www.glassonline.com/infoserv/history.html |title=Glass Online: The History of Glass |access-date=29 October 2007 |url-status=dead |archive-url=https://web.archive.org/web/20111024000436/http://www.glassonline.com/infoserv/history.html |archive-date=24 October 2011 }}</ref> The earliest known glass objects, of the mid-third millennium BC, were ], perhaps initially created as accidental by-products of ] (]s) or during the production of ], a pre-glass ] material made by a process similar to ].<ref>{{cite web |url=https://www.cmog.org/article/life-string-35-centuries-glass-bead |title=All About Glass | Corning Museum of Glass |website=www.cmog.org}}</ref> | |||

| Glass is commonly used in buildings as transparent windows, internal glazed partitions, and as architectural features. It is also possible to use glass as a structural material, for example, in beams and columns, as well as in the form of "fins" for wind reinforcement, which are visible in many glass frontages like large shop windows. Safe load capacity is, however, limited; although glass has a high theoretical yield stress, it is very susceptible to brittle (sudden) failure, and has a tendency to shatter upon localized impact. This particularly limits its use in columns, as there is a risk of vehicles or other heavy objects colliding with and shattering the structural element. One well-known example of a structure made entirely from glass is the northern entrance to ] in ]. | |||

| Early glass was rarely transparent and often contained impurities and imperfections,<ref name="Harvey09" /> and is technically faience rather than true glass, which did not appear until the 15th century BC.<ref>{{Cite journal|last=Karklins|first=Karlis|title=Simon Kwan – Early Chinese Faience and Glass Beads and Pendants|url=https://www.academia.edu/38201095|journal=BEADS: Journal of the Society of Bead Researchers|date=January 2013|language=en}}</ref> However, red-orange glass beads excavated from the ] dated before 1700 BC (possibly as early as 1900 BC) predate sustained glass production, which appeared around 1600 BC in Mesopotamia and 1500 BC in Egypt.<ref>{{Cite book|last=Kenoyer|first=J.M|url=https://www.harappa.com/sites/default/files/pdf/BeadTechnologiesSummary.pdf |archive-url=https://web.archive.org/web/20190708064827/https://www.harappa.com/sites/default/files/pdf/BeadTechnologiesSummary.pdf |archive-date=2019-07-08 |url-status=live|title=South Asian Archaeology|year=2001|location=Paris|pages=157–170|chapter=Bead Technologies at Harappa, 3300–1900 BC: A Comparative Summary}}</ref><ref>{{Cite book|last=McIntosh|first=Jane|url=https://books.google.com/books?id=1AJO2A-CbccC&q=indus+valley+civilization|title=The Ancient Indus Valley: New Perspectives|date=2008|publisher=ABC-CLIO|isbn=978-1-57607-907-2|pages=99|language=en}}</ref> | |||

| Glass in buildings can be of a safety type, including wired, heat strengthened (tempered) and laminated glass. Glass fibre insulation is common in roofs and walls. Foamed glass, made from waste glass, can be used as lightweight, closed-cell insulation. As insulation, glass (e.g., ]) is also used. In the form of long, fluffy-looking sheets, it is commonly found in homes. Fiberglass insulation is used particularly in attics, and is given an R-rating, denoting the insulating ability. | |||

| During the ], there was a rapid growth in ] technology in ] and ].<ref name="Henderson_ancient_glass" /> Archaeological finds from this period include coloured glass ], vessels, and beads.<ref name="Henderson_ancient_glass" /><ref>{{cite web |url=https://dailyhistory.org/How_did_Manufactured_Glass_Develop_in_the_Bronze_Age? |title=How did Manufactured Glass Develop in the Bronze Age? - DailyHistory.org |website=dailyhistory.org}}</ref> | |||

| ===Technological applications=== | |||

| ]s to large sized ] doped glass ] and glass fibres]] | |||

| Much early glass production relied on grinding techniques borrowed from ], such as grinding and carving glass in a cold state.<ref>Wilde, H. "Technologische Innovationen im 2. Jahrtausend v. Chr. Zur Verwendung und Verbreitung neuer Werkstoffe im ostmediterranen Raum". GOF IV, Bd 44, Wiesbaden 2003, 25–26.</ref> | |||

| ] orbiting above earth, containing ]s]] | |||

| The term ''glass'' has its origins in the late ], in the ] making centre at ] (located in current-day Germany) where the ] term ''glesum'' originated, likely from a ] word for a ], ] substance.<ref name="douglas">{{cite book |last=Douglas |first=R.W. |title=A history of glassmaking |publisher=G T Foulis & Co Ltd |place=Henley-on-Thames |year=1972 |isbn=978-0-85429-117-5 |pages=5}}</ref> Glass objects have been recovered across the Roman Empire<ref>{{Cite book |url=https://books.google.com/books?id=bBBkBJN_lJMC&pg=PA45|title=Roman Glass in the Corning Museum of Glass, Volume 3 |last=Whitehouse |first=David |year=2003 |publisher=Hudson Hills |isbn=978-0-87290-155-1 |page=45}}</ref> in domestic, ],<ref>{{Cite book |url=https://books.google.com/books?id=UO5MAQAAMAAJ&pg=PA365|title=The Art Journal |date=1888 |publisher=Virtue and Company |page=365}}</ref> and industrial contexts,<ref>{{Cite journal |url=https://books.google.com/books?id=ouIkAQAAMAAJ&pg=PA259|title=The Manufacture of Glass Milk Bottles |last=Brown |first=A.L. |journal=The Glass Industry |volume=2 |issue=11 |date=November 1921 |publisher=Ashlee Publishing Company |page=259}}</ref> as well as trade items in marketplaces in distant provinces.<ref>Aton, Francesca, '''', Art News, January 25, 2022</ref><ref>McGreevy, Nora, '''', National Geographic, January 28, 2022</ref> Examples of ] have been found outside of the former ] in ],<ref>{{Cite book |url=https://books.google.com/books?id=0zp6iMZoqt0C&pg=PA290|title=Six Dynasties Civilization |last=Dien |first=Albert E. |year=2007 |publisher=Yale University Press |isbn=978-0-300-07404-8 |page=290}}</ref> the ], the ], and ].<ref>{{Cite book |url=https://books.google.com/books?id=xeJMAgAAQBAJ&pg=RA2-PA29|title=The Oxford Companion to Archaeology |last1=Silberman |first1=Neil Asher |last2=Bauer |first2=Alexander A. |year=2012 |publisher=Oxford University Press |isbn=978-0-19-973578-5 |page=29}}</ref> The Romans perfected ], produced by ] and carving through fused layers of different colours to produce a design in relief on the glass object.<ref name="britannica-glass">{{Cite web|url=https://www.britannica.com/technology/glass|title=glass | Definition, Composition, & Facts|website=Encyclopedia Britannica|date=2 October 2023 }}</ref> | |||

| Pure ] (the same chemical compound as ], or, in its ] form, ]) does not absorb ] ] and is used for applications that require transparency in this region. '''Large natural single crystals of quartz''' are pure silicon dioxide, and upon crushing are used for high quality specialty glasses. Synthetic amorphous silica, an almost 100 % pure form of quartz, is the raw material for the most expensive specialty glasses, such as ] core. ] have sections doped with ], which ] transmitted signals by ] emission from within the glass itself. Amorphous SiO<sub>2</sub> is also used as a ] material in ]s due to the smooth and electrically neutral interface it forms with ]. | |||

| ], one of the earliest uses of extensive areas of glass (early 13th-century architecture with restored glass of the 19th century)|alt=Elaborate stained glass windows in the choir of the Basilica of Saint Denis]] | |||

| ]s such as ], ]s, ], ], and ] are based on glass ], ]s, and ]. The glasses used for making these instruments are categorized using a six-digit ], or alternatively a letter-number code from the ] catalogue. For example, ''BK7'' is a low-] ] ], and ''SF10'' is a high-dispersion dense ]. The glasses are arranged by composition, refractive index, and ]. | |||

| In ] West Africa, ] was a manufacturer of glass and glass beads.<ref>Oliver, Roland, and Fagan, Brian M. ''Africa in the Iron Age, c500 B.C. to A.D. 1400''. New York: Cambridge University Press, p. 187. {{ISBN|0-521-20598-0}}.</ref> | |||

| Glass ] is a technique that can be used to incorporate additives that modify the properties of glass that would otherwise be destroyed during high temperature preparation. ] is an example of glass polymerization and enables embedding of organic and bioactive molecules, to add a new level of functionality to glass.<ref></ref> | |||

| Glass was used extensively in Europe during the ]. ] has been found across England during archaeological excavations of both settlement and cemetery sites.<ref>{{Cite book |url=https://books.google.com/books?id=idAVBAAAQBAJ&pg=PP1 |title=Neighbours and Successors of Rome: Traditions of Glass Production and use in Europe and the Middle East in the Later 1st Millennium AD |last1=Keller |first1=Daniel |last2=Price |first2=Jennifer |last3=Jackson |first3=Caroline |year=2014 |publisher=Oxbow Books |isbn=978-1-78297-398-0 |pages=1–41}}</ref> From the 10th century onwards, glass was employed in ] of churches and ]s, with famous examples at ] and the ]. By the 14th century, architects were designing buildings with walls of ] such as ], Paris, (1203–1248) and the East end of ]. With the change in architectural style during the ] period in Europe, the use of large stained glass windows became much less prevalent,<ref>{{Cite book |url=https://archive.org/details/discoveringstain0000tuta |url-access=registration |title=Discovering Stained Glass in Detroit |last1=Tutag |first1=Nola Huse |last2=Hamilton |first2=Lucy |date=1987 |publisher=Wayne State University Press |isbn=978-0-8143-1875-1 |pages=}}</ref> although stained glass had a major revival with ] in the 19th century.<ref>{{Cite book |url=https://archive.org/details/encyclopediaofam00hunt |url-access=registration |title=Encyclopedia of American architecture |last1=Packard |first1=Robert T. |last2=Korab |first2=Balthazar |last3=Hunt |first3=William Dudley |date=1980 |publisher=McGraw-Hill |isbn=978-0-07-048010-0 |pages=}}</ref> | |||

| During the 13th century, the island of ], ], became a centre for glass making, building on medieval techniques to produce colourful ornamental pieces in large quantities.<ref name=britannica-glass /> ] makers developed the exceptionally clear colourless glass ], so called for its resemblance to natural crystal, which was extensively used for windows, mirrors, ships' lanterns, and lenses.<ref name="Harvey09" /> In the 13th, 14th, and 15th centuries, enamelling and ] on glass vessels were perfected in Egypt and Syria.<ref name="EB1911-incorp" /> Towards the end of the 17th century, ] became an important region for glass production, remaining so until the start of the 20th century. By the 17th century, glass in the Venetian tradition was also being produced in ]. In about 1675, ] invented ] glass, with ] becoming fashionable in the 18th century.<ref name=britannica-glass /> Ornamental glass objects became an important art medium during the ] period in the late 19th century.<ref name="britannica-glass" /> | |||

| ==Glass production== | |||

| {{main|Glass production|Float glass}} | |||

| Throughout the 20th century, new ] techniques led to the widespread availability of glass in much larger amounts, making it practical as a building material and enabling new applications of glass.<ref>{{Cite book |url=https://books.google.com/books?id=jm9hGqECbXcC&pg=PA705 |title=Global Roadmap for Ceramic and Glass Technology |last=Freiman |first=Stephen |year=2007 |publisher=John Wiley & Sons |isbn=978-0-470-10491-0 |pages=705}}</ref> In the 1920s a ]-etch process was developed, in which art was etched directly into the mould so that each cast piece emerged from the mould with the image already on the surface of the glass. This reduced manufacturing costs and, combined with a wider use of coloured glass, led to cheap glassware in the 1930s, which later became known as ].<ref>{{cite web |title=Depression Glass |url=http://www.glassonweb.com/articles/article/201/ |access-date=2007-10-19 |archive-date=2 December 2014 |archive-url=https://web.archive.org/web/20141202110304/http://www.glassonweb.com/articles/article/201/ |url-status=dead }}</ref> In the 1950s, ], ], developed the ] process, producing high-quality distortion-free flat sheets of glass by floating on molten ].<ref name="Harvey09" /> Modern multi-story buildings are frequently constructed with ] made almost entirely of glass.<ref>{{Cite book |url=https://books.google.com/books?id=b_PmZAzJecYC&pg=PT187 |title=Sustainable Renovation: Strategies for Commercial Building Systems and Envelope |last1=Gelfand |first1=Lisa |last2=Duncan |first2=Chris |year=2011 |publisher=John Wiley & Sons |pages=187 |isbn=978-1-118-10217-6}}</ref> ] has been widely applied to vehicles for windscreens.<ref>{{Cite book |url=https://books.google.com/books?id=g-YCKEPYMpYC&pg=PA274 |title=Photodermatology |last1=Lim |first1=Henry W. |last2=Honigsmann |first2=Herbert |last3=Hawk |first3=John L.M. |year=2007 |publisher=CRC Press |pages=274 |isbn=978-1-4200-1996-4}}</ref> Optical glass for spectacles has been used since the Middle Ages.<ref>{{cite book|title=The Properties of Optical Glass|first1=Hans|last1=Bach|first2=Norbert|last2=Neuroth|publisher=Springer|year=2012|url=https://books.google.com/books?id=y3nnCAAAQBAJ&pg=PA267|isbn=978-3-642-57769-7|pages=267}}</ref> The production of lenses has become increasingly proficient, aiding ]s<ref>{{cite book |first1=Ian S. |last1=McLean |title=Electronic Imaging in Astronomy: Detectors and Instrumentation |url=https://books.google.com/books?id=FGHhZf-k8SkC&pg=PA78 |publisher=Springer Science & Business Media |year=2008 |pages=78 |isbn=978-3-540-76582-0}}</ref> as well as having other applications in medicine and science.<ref name="glassalliance">{{cite web|url=https://www.glassallianceeurope.eu/en/applications |title=Glass Applications – Glass Alliance Europe |publisher=Glassallianceeurope.eu |access-date=2020-03-01}}</ref> Glass is also employed as the aperture cover in many ] collectors.<ref>{{Cite book |url=https://books.google.com/books?id=QNTKBQAAQBAJ&pg=PA122 |title=Solar Energy Sciences and Engineering Applications |last1=Enteria |first1=Napoleon |last2=Akbarzadeh |first2=Aliakbar |pages=122 |year=2013 |publisher=CRC Press |isbn=978-0-203-76205-9}}</ref> | |||

| ] from ], ], Sweden. In the middle the mark from the ] pipe]] | |||

| ===Glass production history=== | |||

| In the 21st century, glass manufacturers have developed different brands of ] for widespread application in ]s for ]s, ]s, and many other types of ]s. These include ], developed and manufactured by ], ]'s ] and ]'s Xensation.<ref>{{cite web |url=http://www.physnews.com/materials-news/cluster251747226/ |title=Gorilla Glass maker unveils ultra-thin and flexible Willow Glass |work=Physics News |access-date=2013-11-01 |url-status=dead |archive-url=https://web.archive.org/web/20131106075448/http://www.physnews.com/materials-news/cluster251747226/ |archive-date=6 November 2013 }}</ref><ref>{{cite web |url=http://www.schott.com/xensation/english/index.html |title=Xensation |publisher=] |access-date=2013-11-01 |url-status=live |archive-url=https://web.archive.org/web/20131103224742/http://www.schott.com/xensation/english/index.html |archive-date=2013-11-03 }}</ref><ref name="gensix">{{cite web |url=https://www.engadget.com/2018/07/18/corning-unveils-gorilla-glass-6/ |title=Gorilla Glass 6 gives phones a better shot at surviving multiple drops |publisher=Engadget |date=19 July 2018 |first=Jon |last=Fingas }}</ref> | |||

| Glass melting technology has passed through several stages:<ref name=ullmann>B. H. W. S. de Jong, "Glass"; in "Ullmann's Encyclopedia of Industrial Chemistry"; 5th edition, vol. A12, VCH Publishers, Weinheim, Germany, 1989, ISBN 3-527-20112-5, p 365-432.</ref> | |||

| == Physical properties == | |||

| * Glass was manufactured in open pits, ca. 3000 B.C. until the invention of the blowpipe in ca. 250 B.C. | |||

| === Optical === | |||

| {{Main|Optical glass}} | |||

| Glass is in widespread use in optical systems due to its ability to refract, reflect, and transmit light following ]. The most common and oldest applications of glass in optics are as ], ]s, ]s, and ]s.<ref name="Bach12">{{cite book |title=The Properties of Optical Glass |first1=Hans |last1=Bach |first2=Norbert |last2=Neuroth |publisher=Springer |year=2012|url=https://books.google.com/books?id=y3nnCAAAQBAJ&pg=PA1 |pages=1–11 |isbn=978-3-642-57769-7}}</ref> The key optical properties ], ], and ], of glass are strongly dependent on chemical composition and, to a lesser degree, its thermal history.<ref name=Bach12 /> Optical glass typically has a refractive index of 1.4 to 2.4, and an ] (which characterises dispersion) of 15 to 100.<ref name=Bach12 /> The refractive index may be modified by high-density (refractive index increases) or low-density (refractive index decreases) additives.<ref>{{Cite book |url=https://books.google.com/books?id=-0DOBQAAQBAJ&pg=PA70 |title=Physical Properties of Materials, Second Edition |last=White |first=Mary Anne |authorlink1=Mary Anne White |year=2011 |pages=70 |publisher=CRC Press|isbn=978-1-4398-9532-0}}</ref> | |||

| Glass transparency results from the absence of ] which ] in polycrystalline materials.<ref name="Carter-Norton">{{Cite book |url=https://books.google.com/books?id=aE_VQ8I24OoC&pg=PA583 |title=Ceramic Materials: Science and Engineering |last1=Carter |first1=C. Barry |first2=M. Grant |last2= Norton |year=2007| publisher=Springer Science & Business Media| pages=583|isbn=978-0-387-46271-4 }}</ref> Semi-opacity due to crystallization may be induced in many glasses by maintaining them for a long period at a temperature just insufficient to cause fusion. In this way, the crystalline, devitrified material, known as Réaumur's glass ] is produced.<ref name="EB1911-incorp">{{EB1911|inline=1 |wstitle=Glass |volume=12 |page=86}}</ref><ref name="Mysen05">{{cite book|last1=Mysen|first1=Bjorn O.|last2=Richet|first2=Pascal|title=Silicate Glasses and Melts: Properties and Structure|publisher=Elsevier|year=2005|pages=10}}</ref> Although generally transparent to visible light, glasses may be ] to other ]. While silicate glasses are generally opaque to ] wavelengths with a transmission cut-off at 4 μm, heavy-metal ] and ] glasses are transparent to infrared wavelengths of 7 to 18 μm.<ref name=brittanica-industrial /> The addition of metallic oxides results in different coloured glasses as the metallic ions will absorb wavelengths of light corresponding to specific colours.<ref name=brittanica-industrial /> | |||

| * The mobile wood-fired melting pot furnace was used until around the 17th century by traveling glass manufacturers. | |||

| === Other === | |||

| * Around 1688, a process for ] glass was developed, which led to glass becoming a much more commonly used material.{{Fact|date=December 2007}} | |||

| {{See also|List of physical properties of glass|Corrosion#Corrosion of glass|Strength of glass}} | |||

| ] | |||

| In the manufacturing process, glasses can be poured, formed, extruded and moulded into forms ranging from flat sheets to highly intricate shapes.<ref>{{Cite book |url=https://books.google.com/books?id=BZUtFQNuNgMC&pg=PA60 |title=Handbook of Physical Vapor Deposition (PVD) Processing |last=Mattox |first=D.M. |year=2014 |page=60 |publisher=Cambridge University Press |isbn=978-0-08-094658-0}}</ref> The finished product is brittle but can be ] or ] to enhance durability.<ref>{{Cite book|url=https://books.google.com/books?id=D7Z8ywb3QggC&pg=PA361|title=Glasses and the Vitreous State|last=Zarzycki|first=Jerzy|year=1991|publisher=Cambridge University Press|isbn=978-0-521-35582-7|pages=361}}</ref><ref>{{Cite book|url=https://books.google.com/books?id=CL8Z38FaPsAC&pg=PA365|title=Collision Repair and Refinishing: A Foundation Course for Technicians|last1=Thomas|first1=Alfred|last2=Jund|first2=Michael|year=2013|pages=365|publisher=Cengage Learning |isbn=978-1-133-60187-6}}</ref> Glass is typically inert, resistant to chemical attack, and can mostly withstand the action of water, making it an ideal material for the manufacture of containers for foodstuffs and most chemicals.<ref name="Harvey09" /><ref name="Gardner-1949">{{Cite book|url=https://books.google.com/books?id=yYQ3BMs9Ql0C&pg=PA13|title=Research and Development in Applied Optics and Optical Glass at the National Bureau of Standards: A Review and Bibliography|last1=Gardner|first1=Irvine Clifton|last2=Hahner|first2=Clarence H.|date=1949|publisher=U.S. Government Printing Office|page=13|isbn=9780598682413}}</ref><ref>{{Cite book|url=https://books.google.com/books?id=rJTBCQAAQBAJ&pg=PA550|title=Food Safety in the 21st Century: Public Health Perspective|last1=Dudeja|first1=Puja|last2=Gupta|first2=Rajul K.| page=550 |last3=Minhas|first3=Amarjeet Singh|year=2016|publisher=Academic Press|isbn=978-0-12-801846-0}}</ref> Nevertheless, although usually highly resistant to chemical attack, glass will corrode or dissolve under some conditions.<ref name="Gardner-1949" /><ref name="Bengisu 2013">{{Cite book|url=https://books.google.com/books?id=PXD8CAAAQBAJ&pg=PA360|title=Engineering Ceramics|last=Bengisu|first=M.|year=2013|publisher=Springer Science & Business Media|isbn=978-3-662-04350-9|page=360}}</ref> The materials that make up a particular glass composition affect how quickly the glass corrodes. Glasses containing a high proportion of ] or ] elements are more susceptible to corrosion than other glass compositions.<ref>{{Cite book|url=https://books.google.com/books?id=IVe7CgAAQBAJ&pg=PA141|title=Materials Degradation and Its Control by Surface Engineering|last1=Batchelor|first1=Andrew W.|last2=Loh|first2=Nee Lam|last3=Chandrasekaran|first3=Margam|year=2011|publisher=World Scientific|page=141|isbn=978-1-908978-14-1}}</ref><ref name="Chawla93">{{Cite book|url=https://books.google.com/books?id=_NXYRgHnnqkC&pg=PA328|pages=327–328|title=Materials Selection for Corrosion Control|last=Chawla|first=Sohan L.|date=1993|publisher=ASM International|isbn=978-1-61503-728-5}}</ref> | |||

| The density of glass varies with chemical composition with values ranging from {{convert|2.2|g/cm3|kg/m3}} for ] to {{convert|7.2|g/cm3|kg/m3}} for dense flint glass.<ref>{{cite Q|Q87511351}}<!--"Density of Glass" in The Physics Factbook--></ref> Glass is stronger than most metals, with a theoretical ] for pure, flawless glass estimated at {{convert|14|to|35|GPa|psi}} due to its ability to undergo reversible compression without fracture. However, the presence of scratches, bubbles, and other microscopic flaws lead to a typical range of {{convert|14|to|175|MPa|psi}} in most commercial glasses.<ref name="brittanica-industrial">{{Cite web|url=https://www.britannica.com/topic/glass-properties-composition-and-industrial-production-234890|title=Industrial glass – Properties of glass|website=Encyclopedia Britannica}}</ref> Several processes such as ] can increase the strength of glass.<ref>{{cite web|url=https://www.pilkington.com/en-gb/uk/architects/glass-information/functions-of-glass/mechanicalfunctionsofglass/glass-strength|title=Glass Strength|website=www.pilkington.com|access-date=2017-11-24|url-status=live|archive-url=https://web.archive.org/web/20170726123604/http://www.pilkington.com/en-gb/uk/architects/glass-information/functions-of-glass/mechanicalfunctionsofglass/glass-strength|archive-date=26 July 2017}}</ref> Carefully drawn flawless ]s can be produced with a strength of up to {{convert|11.5|GPa|psi}}.<ref name=brittanica-industrial /> | |||

| * The local pot furnace, fired by wood and coal was used between 1600 and 1850. | |||

| {{Further|topic=the tiny glass flakes formed during glass vial manufacturing |Spicule (glass manufacture)|label1=Spicule}} | |||

| === Reputed flow === | |||

| * The ] of creating ] was used in the ] for the first time in the 1820s. It was used to commercially produce windows.{{Fact|date=December 2007}} | |||

| The observation that old windows are sometimes found to be thicker at the bottom than at the top is often offered as supporting evidence for the view that glass flows over a timescale of centuries, the assumption being that the glass has exhibited the liquid property of flowing from one shape to another.<ref>{{cite news|url=https://www.nytimes.com/2008/07/29/science/29glass.html?ex=1375070400&en=048ade4011756b24&ei=5124&partner=permalink&exprod=permalink|title=The Nature of Glass Remains Anything but Clear|work=The New York Times|access-date=29 July 2008|date=29 July 2008|author=Kenneth Chang|url-status=live|archive-url=https://web.archive.org/web/20090424094929/http://www.nytimes.com/2008/07/29/science/29glass.html?ex=1375070400&en=048ade4011756b24&ei=5124&partner=permalink&exprod=permalink|archive-date=24 April 2009}}</ref> This assumption is incorrect, as once solidified, glass stops flowing. The sags and ripples observed in old glass were already there the day it was made; manufacturing processes used in the past produced sheets with imperfect surfaces and non-uniform thickness (the near-perfect ] used today only became widespread in the 1960s).<ref name=Gibbs /> | |||

| A 2017 study computed the rate of flow of the medieval glass used in ] from the year 1268. The study found that the room temperature viscosity of this glass was roughly 10<sup>24</sup>{{nbsp}}]·] which is about 10<sup>16</sup> times less viscous than a previous estimate made in 1998, which focused on soda-lime silicate glass. Even with this lower viscosity, the study authors calculated that the maximum flow rate of medieval glass is 1 ] per billion years, making it impossible to observe in a human timescale.<ref>{{cite journal | last1=Gulbiten | first1=Ozgur | last2=Mauro | first2=John C. | last3=Guo | first3=Xiaoju | last4=Boratav | first4=Olus N. | title=Viscous flow of medieval cathedral glass | journal=Journal of the American Ceramic Society| volume=101 | issue=1 | date=3 August 2017 | issn=0002-7820 | doi=10.1111/jace.15092 | pages=5–11}}</ref><ref>{{Cite web |title=Glass viscosity calculations definitively debunk the myth of observable flow in medieval windows |last=Gocha |first=April |work=The American Ceramic Society |date=3 August 2017 |url= https://ceramics.org/ceramic-tech-today/glass-viscosity-calculations-definitively-debunk-the-myth-of-observable-flow-in-medieval-windows}}</ref> | |||

| * The invention of the glass pressing machine in 1827 allowed the mass production of inexpensive glass products<ref>http://www.redsofts.com/articles/read/151/61135/Cut_Glass_And_Glass_Blowing_History_And_Development.html</ref>. | |||

| == Types == | |||

| * The gas-heated melting pot and tank furnaces dating from 1860, followed by the electric furnace of 1910. | |||

| === Silicate glasses === | |||

| ] (silica) is the main raw material in commercial glass production|alt=Close-up photograph of sand]] | |||

| ] (SiO<sub>2</sub>) is a common fundamental constituent of glass. ] is a glass made from chemically pure silica.<ref name="Chawla93" /> It has very low thermal expansion and excellent resistance to ], being able to survive immersion in water while red hot, resists high temperatures (1000–1500 °C) and chemical weathering, and is very hard. It is also transparent to a wider spectral range than ordinary glass, extending from the visible further into both the ] and ] ranges, and is sometimes used where transparency to these wavelengths is necessary. Fused quartz is used for high-temperature applications such as furnace tubes, lighting tubes, melting crucibles, etc.<ref name="Seafriends-1994">{{cite web|url=http://www.seafriends.org.nz/oceano/seasand.htm|title=Mining the sea sand|url-status=live|archive-url=https://web.archive.org/web/20120229061512/http://www.seafriends.org.nz/oceano/seasand.htm|archive-date=29 February 2012|website=Seafriends|date=1994-02-08|access-date=2012-05-15}}</ref> However, its high melting temperature (1723 °C) and viscosity make it difficult to work with. Therefore, normally, other substances (fluxes) are added to lower the melting temperature and simplify glass processing.<ref name="Chemistry-explained">{{cite web|url=http://www.chemistryexplained.com/Ge-Hy/Glass.html|access-date=1 April 2015|title=Glass – Chemistry Encyclopedia|url-status=live|archive-url=https://web.archive.org/web/20150402113454/http://www.chemistryexplained.com/Ge-Hy/Glass.html|archive-date=2 April 2015}}</ref> | |||

| ==== Soda–lime glass ==== | |||

| * Hand-blown ] was replaced in the 20th century by rolled plate glass.{{Fact|date=December 2007}} | |||

| {{Main|Soda–lime glass}} | |||

| ] (Na<sub>2</sub>CO<sub>3</sub>, "soda") is a common additive and acts to lower the glass-transition temperature. However, ] is ], so ] (CaO, ], generally obtained from ]), along with ] (MgO), and ] (Al<sub>2</sub>O<sub>3</sub>), are commonly added to improve chemical durability. Soda–lime glasses (Na<sub>2</sub>O) + lime (CaO) + magnesia (MgO) + alumina (Al<sub>2</sub>O<sub>3</sub>) account for over 75% of manufactured glass, containing about 70 to 74% silica by weight.<ref name="Chawla93" /><ref name="ullmann">B.H.W.S. de Jong, "Glass"; in "Ullmann's Encyclopedia of Industrial Chemistry"; 5th edition, vol. A12, VCH Publishers, Weinheim, Germany, 1989, {{ISBN|978-3-527-20112-9}}, pp. 365–432.</ref> Soda–lime–silicate glass is transparent, easily formed, and most suitable for window glass and tableware.<ref name="Spence-2016">{{Cite book|url=https://books.google.com/books?id=KX5TCwAAQBAJ&pg=PA509|title=Construction Materials, Methods and Techniques|last1=Spence|first1=William P.|last2=Kultermann|first2=Eva|year=2016|publisher=Cengage Learning|isbn=978-1-305-08627-2|pages=510–526}}</ref> However, it has a high thermal expansion and poor resistance to heat.<ref name="Spence-2016" /> Soda–lime glass is typically used for ]s, ]s, ]s, and ]s.<ref name="Chemistry-explained" /> | |||

| ==== Borosilicate glass ==== | |||

| * The ] process was invented in the 1950s. | |||

| ] ] ] |alt=Refer to caption]] | |||

| ]es (e.g. ], ]) typically contain 5–13% ] (B<sub>2</sub>O<sub>3</sub>).<ref name="Chemistry-explained" /> Borosilicate glasses have fairly low ] (7740 Pyrex CTE is 3.25{{e|-6}}/°C<ref>{{cite web|url=http://www.quartz.com/pxprop.pdf|title=Properties of PYREX®, PYREXPLUS® and Low Actinic PYREX Code 7740 Glasses|publisher=Corning, Inc.|url-status=live|archive-url=https://web.archive.org/web/20120113050839/http://www.quartz.com/pxprop.pdf|archive-date=13 January 2012|access-date=2012-05-15}}</ref> as compared to about 9{{e|-6}}/°C for a typical soda–lime glass<ref>{{cite web|url=http://www.us.schott.com/tubing/media/selector/datasheets/english/schott-tubing_datasheet_ar-glas_english.pdf|title=AR-GLAS® Technical Data|url-status=live|archive-url=https://web.archive.org/web/20120612224929/http://www.us.schott.com/tubing/media/selector/datasheets/english/schott-tubing_datasheet_ar-glas_english.pdf|archive-date=12 June 2012|publisher=Schott, Inc.}}</ref>). They are, therefore, less subject to ] caused by ] and thus less vulnerable to ] from ]. They are commonly used for e.g. ], ], and sealed beam car ]s.<ref name="Chemistry-explained" /> | |||

| === |

==== Lead glass ==== | ||

| {{Main|Lead glass}}{{See also|Lead poisoning}} | |||

| ] (silica) as main raw material for commercial glass production]] | |||

| The addition of ] into silicate glass lowers the melting point and ] of the melt.<ref>{{Cite book |url=https://books.google.com/books?id=ZeF_QLW6-xsC&pg=PA125 |title=Introduction to Glass Science and Technology |last=Shelby |first=J.E. |year=2017 |page=125 |publisher=Royal Society of Chemistry |isbn=978-0-85404-639-3}}</ref> The high density of lead glass (silica + lead oxide (PbO) + potassium oxide (K<sub>2</sub>O) + soda (Na<sub>2</sub>O) + zinc oxide (ZnO) + alumina) results in a high electron density, and hence high refractive index, making the look of glassware more brilliant and causing noticeably more ] and increased ].<ref name="Chawla93" /><ref name="Schwartz-2002">{{Cite book |url=https://books.google.com/books?id=0ETMBQAAQBAJ&pg=PA352 |title=Encyclopedia of Materials, Parts and Finishes |edition=Second |last=Schwartz |first=Mel |year=2002 |page =352 |publisher=CRC Press |isbn=978-1-4200-1716-8}}</ref> Lead glass has a high elasticity, making the glassware more workable and giving rise to a clear "ring" sound when struck. However, lead glass cannot withstand high temperatures well.<ref name="Seafriends-1994" /> Lead oxide also facilitates the solubility of other metal oxides and is used in coloured glass. The viscosity decrease of lead glass melt is very significant (roughly 100 times in comparison with soda glass); this allows easier removal of bubbles and working at lower temperatures, hence its frequent use as an additive in ]s and ]s. The high ] of the Pb<sup>2+</sup> ion renders it highly immobile and hinders the movement of other ions; lead glasses therefore have high electrical resistance, about two orders of magnitude higher than soda–lime glass (10<sup>8.5</sup> vs 10<sup>6.5</sup> Ω⋅cm, ] at 250 °C).<ref>{{Cite book|url=https://books.google.com/books?id=ASIYuNCp81YC&pg=PA158|title=Ceramic and Glass Materials: Structure, Properties and Processing|last1=Shackelford|first1=James F.|last2=Doremus|first2=Robert H.|date=2008-04-12|publisher=Springer Science & Business Media|isbn=978-0-387-73362-3 |page=158}}</ref> | |||

| ==== Aluminosilicate glass ==== | |||

| Pure ] (SiO<sub>2</sub>) has a "glass melting point"— at a ] of 10 ] (100 ])— of over 2300 ] (4200 ]). While pure silica can be made into glass for special applications (see ]), other substances are added to common glass to simplify processing. One is ] (Na<sub>2</sub>CO<sub>3</sub>), which lowers the melting point to about 1500 °C (2700 °F) in ]; "]" refers to the original source of sodium carbonate in the ] obtained from certain plants. However, the soda makes the glass water soluble, which is usually undesirable, so ] (] (CaO), generally obtained from ]), some magnesium oxide (MgO) and aluminium oxide are added to provide for a better chemical durability. The resulting glass contains about 70 to 74 percent silica by weight and is called a ].<ref name=ullmann/> Soda-lime glasses account for about 90 percent of manufactured glass. | |||

| Aluminosilicate glass typically contains 5–10% ] (Al<sub>2</sub>O<sub>3</sub>). Aluminosilicate glass tends to be more difficult to melt and shape compared to borosilicate compositions but has excellent thermal resistance and durability.<ref name="Chemistry-explained" /> Aluminosilicate glass is extensively used for ],<ref name="Askeland-2008">{{Cite book|url=https://books.google.com/books?id=TL4j-jDXsk0C&pg=PA485|title=Essentials of Materials Science & Engineering|last1=Askeland|first1=Donald R.|last2=Fulay|first2=Pradeep P.|year=2008|page=485|publisher=Cengage Learning|isbn=978-0-495-24446-2}}</ref> used for making glass-reinforced plastics (boats, fishing rods, etc.), top-of-stove cookware, and halogen bulb glass.<ref name="Seafriends-1994" /><ref name="Chemistry-explained" /> | |||

| ==== Other oxide additives ==== | |||

| As well as soda and lime, most common glass has other ingredients added to change its properties. ] glass, such as ] or ], is more 'brilliant' because the increased ] causes noticeably more "sparkles", while ] may be added to change the thermal and electrical properties, as in ]. Adding ] also increases the refractive index. ] gives glass a high refractive index and low dispersion, and was formerly used in producing high-quality lenses, but due to its ] has been replaced by ] in modern glasses. Large amounts of ] are used in glass that absorbs ] energy, such as heat absorbing filters for movie projectors, while ] can be used for glass that absorbs ] wavelengths (biologically damaging ionizing radiation). | |||

| The addition of ] also increases the refractive index. ] gives glass a high refractive index and low dispersion and was formerly used in producing high-quality lenses, but due to its ] has been replaced by ] in modern eyeglasses.<ref>{{cite web|url=http://www.historyofglass.com/glass-making-process/glass-ingredients/|title=Glass Ingredients – What is Glass Made Of?|website=www.historyofglass.com|access-date=2017-04-23|url-status=live|archive-url=https://web.archive.org/web/20170423155431/http://www.historyofglass.com/glass-making-process/glass-ingredients/|archive-date=23 April 2017}}</ref> Iron can be incorporated into glass to absorb ] radiation, for example in heat-absorbing filters for movie projectors, while ] can be used for glass that absorbs ] wavelengths.<ref>{{cite book |last=Pfaender |first=Heinz G. |title=Schott guide to glass |url=https://books.google.com/books?id=v5q4Hje3iFgC&pg=PA135 |access-date=8 February 2011 |year=1996 |publisher=Springer |isbn=978-0-412-62060-7 |pages=135, 186 |url-status=live |archive-url=https://web.archive.org/web/20130525185349/http://books.google.com/books?id=v5q4Hje3iFgC&pg=PA135 |archive-date=25 May 2013}}</ref> ] lowers the ] of glass. Fluorine is highly ] and lowers the polarizability of the material. Fluoride silicate glasses are used in the manufacture of ]s as an insulator.<ref>{{cite book |last1=Doering |first1=Robert |last2=Nishi |first2=Yoshio |url=https://books.google.com/books?id=PsVVKz_hjBgC&pg=SA12-PA3 |title=Handbook of semiconductor manufacturing technology |pages=12–13 |publisher=CRC Press |year=2007 |isbn=978-1-57444-675-3}}</ref> | |||

| ==== Glass-ceramics ==== | |||

| Besides the chemicals mentioned, in some furnaces recycled glass ("cullet") is added, originating from the same factory or other sources. Cullet leads to savings not only in the raw materials, but also in the energy consumption of the glass furnace. However, impurities in the cullet may lead to product and equipment failure. Fining agents such as ], ], or ] are added to reduce the bubble content in the glass.<ref name=ullmann/> | |||

| {{Main|Glass-ceramic}} | |||

| ] with negligible ] |alt=A cooktop with two of its eyes turned on]] | |||

| ] materials contain both non-crystalline glass and ] ] phases. They are formed by controlled nucleation and partial crystallisation of a base glass by heat treatment.<ref name="Holand-glass-ceramics">{{cite book |url=https://books.google.com/books?id=Bw_Yz52jdFQC&pg=PA1 |title=Glass Ceramic Technology |last1=Holand |first1=Wolfram |last2=Beall |first2=George H. |year=2012 |pages=1–38 |publisher=John Wiley & Sons |isbn=978-1-118-26592-5}}</ref> Crystalline grains are often embedded within a non-crystalline intergranular phase of ]. Glass-ceramics exhibit advantageous thermal, chemical, biological, and dielectric properties as compared to metals or organic polymers.<ref name=Holand-glass-ceramics /> | |||

| The most commercially important property of glass-ceramics is their imperviousness to thermal shock. Thus, glass-ceramics have become extremely useful for countertop cooking and industrial processes. The negative ] coefficient (CTE) of the crystalline ceramic phase can be balanced with the positive CTE of the glassy phase. At a certain point (~70% crystalline) the glass-ceramic has a net CTE near zero. This type of ] exhibits excellent mechanical properties and can sustain repeated and quick temperature changes up to 1000 °C.<ref name="MOD">{{cite book |last=Richerson |first=David W. |title=Modern ceramic engineering : properties, processing and use in design |year=1992 |publisher=Dekker |pages=577–578 |location=New York |isbn=978-0-8247-8634-2 |edition=2nd}}</ref><ref name=Holand-glass-ceramics /> | |||

| A further raw material used in the production of soda-lime and fiber glass is calumite, which is a glassy granular by-product of the iron making industry, containing mainly silica, calcium oxide, alumina, magnesium oxide (and traces of iron oxide).<ref></ref> | |||

| ==== Fibreglass ==== | |||

| For obtaining the desired glass composition, the correct raw material mixture (batch) must be determined by ]. | |||

| {{Main|Fiberglass|Glass wool}} | |||

| ] (also called glass fibre reinforced plastic, GRP) is a ] made by reinforcing a plastic ] with ]s. It is made by melting glass and stretching the glass into fibres. These fibres are woven together into a cloth and left to set in a plastic resin.<ref name="Parkyn">{{cite book |url=https://books.google.com/books?id=gfEkBQAAQBAJ&pg=PA3 |title=Glass Reinforced Plastics |last=Parkyn |first=Brian |publisher=Elsevier |year=2013 |pages=3–41|isbn=978-1-4831-0298-6 }}</ref><ref>{{cite book |last= Mayer |first= Rayner M. |title= Design with reinforced plastics |page= 7 |publisher= Springer |year= 1993 |url= https://books.google.com/books?id=XQFJego9nGUC&pg=PA7 |isbn= 978-0-85072-294-9}}</ref><ref name="propertiesofmatter">{{cite web|url=http://www.propertiesofmatter.si.edu/teamwork.html|title=Properties of Matter Reading Selection: Perfect Teamwork|website=www.propertiesofmatter.si.edu|access-date=2017-04-25|url-status=dead|archive-url=https://web.archive.org/web/20160512174222/http://www.propertiesofmatter.si.edu/teamwork.html|archive-date=12 May 2016}}</ref> | |||

| Fibreglass has the properties of being lightweight and corrosion resistant and is a good ] enabling its use as ] and for electronic housing for consumer products. Fibreglass was originally used in the United Kingdom and United States during ] to manufacture ]s. Uses of fibreglass include building and construction materials, boat hulls, car body parts, and aerospace composite materials.<ref name="brittanica-fibreglass">{{Cite web|url=https://www.britannica.com/technology/fiberglass|title=Fibreglass | glass|website=Encyclopedia Britannica|date=28 August 2024 }}</ref><ref name=Parkyn /><ref name=propertiesofmatter /> | |||

| ] is an excellent ] and ] insulation material, commonly used in buildings (e.g. ] and ]), and plumbing (e.g. ]), and ].<ref name=brittanica-fibreglass /> It is produced by forcing molten glass through a fine mesh by ] and breaking the extruded glass fibres into short lengths using a stream of high-velocity air. The fibres are bonded with an adhesive spray and the resulting wool mat is cut and packed in rolls or panels.<ref name=brittanica-industrial /> | |||

| ===Contemporary glass production=== | |||

| === Non-silicate glasses === | |||

| Following the ] preparation and mixing the raw materials are transported to the furnace. ] for mass production is melted in ]. Smaller scale furnaces for specialty glasses include electric melters, pot furnaces and day tanks.<ref name=ullmann/> | |||

| ] (CD). ] forms the basis of rewritable CD and DVD solid-state memory technology.<ref name="Greer05">{{cite journal |last1=Greer |first1=A. Lindsay |doi=10.1038/4371246a |journal=Nature |volume=437 |pages=1246–1247 |year=2005 |title=Materials science: Changing Face of the Chameleon |pmid=16251941 |last2=Mathur |first2=N |issue=7063 |bibcode=2005Natur.437.1246G|s2cid=6972351 |doi-access=free }}</ref>|alt=A CD]] | |||

| Besides common silica-based glasses many other ] and ] materials may also form glasses, including ], ]s, ]s, ]s, ], ]s, germanates (glasses based on ]), tellurites (glasses based on TeO<sub>2</sub>), antimonates (glasses based on Sb<sub>2</sub>O<sub>3</sub>), arsenates (glasses based on As<sub>2</sub>O<sub>3</sub>), titanates (glasses based on TiO<sub>2</sub>), tantalates (glasses based on Ta<sub>2</sub>O<sub>5</sub>), ]s, ]s, ], ], and many other substances.<ref name="Elliot84" /> Some of these glasses (e.g. ] (GeO<sub>2</sub>, Germania), in many respects a structural analogue of silica, ], ], ], ], and ] glasses) have physicochemical properties useful for their application in ] ]s in communication networks and other specialised technological applications.<ref>{{Cite book|url=https://books.google.com/books?id=gL-RDgAAQBAJ&pg=PA214|title=Technological Advances in Tellurite Glasses: Properties, Processing, and Applications|last1=Rivera|first1=V. A. G.|last2=Manzani|first2=Danilo|date=2017-03-30|publisher=Springer|isbn=978-3-319-53038-3|page=214|language=en}}</ref><ref>{{Cite journal | |||

| |last1=Jiang|first1=Xin|last2=Lousteau|first2=Joris|last3=Richards|first3=Billy|last4=Jha|first4=Animesh|date=2009-09-01 | |||

| |title=Investigation on germanium oxide-based glasses for infrared optical fibre development | |||

| |journal=Optical Materials|volume=31|issue=11|pages=1701–1706|doi=10.1016/j.optmat.2009.04.011 |bibcode=2009OptMa..31.1701J | |||

| }}</ref> | |||

| Silica-free glasses may often have poor glass-forming tendencies. Novel techniques, including containerless processing by ] (cooling the melt whilst it floats on a gas stream) or ] (pressing the melt between two metal anvils or rollers), may be used to increase the cooling rate or to reduce crystal nucleation triggers.<ref>{{cite journal|author1=J. W. E. Drewitt|author2=S. Jahn|author3=L. Hennet|title=Configurational constraints on glass formation in the liquid calcium aluminate system|journal=Journal of Statistical Mechanics: Theory and Experiment|year=2019|volume=2019|issue=10|page=104012|doi=10.1088/1742-5468/ab47fc|arxiv=1909.07645|bibcode=2019JSMTE..10.4012D|s2cid=202583753}}</ref><ref>{{cite journal|author1=C. J. Benmore |author2=J. K. R. Weber|year=2017|title=Aerodynamic levitation, supercooled liquids and glass formation|journal=Advances in Physics: X|volume=2|issue=3|pages=717–736|doi= 10.1080/23746149.2017.1357498|bibcode=2017AdPhX...2..717B|doi-access=free}}</ref><ref>{{cite journal|last=Davies|first=H. A.|author2=Hull J. B. |title=The formation, structure and crystallization of non-crystalline nickel produced by splat-quenching|journal=Journal of Materials Science|year=1976|volume=11|issue=2|pages=707–717|doi=10.1007/BF00551430|bibcode=1976JMatS..11..215D|s2cid=137403190}}</ref> | |||

| After melting, homogenization and refining (removal of bubbles) the glass is ]. Flat glass for windows and similar applications is formed by the ] process, developed between 1953 and 1957 by Sir ] and Kenneth Bickerstaff of the UK's Pilkington Brothers, which created a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. | |||

| Container glass for common bottles and jars is formed by ] methods. Further glass forming techniques are summarized in the table ]. | |||

| ==== Amorphous metals ==== | |||

| Once the desired form is obtained, glass is usually ] for the removal of stresses. | |||

| {{Main|Amorphous metal}} | |||

| ] | |||

| In the past, small batches of ]s with high surface area configurations (ribbons, wires, films, etc.) have been produced through the implementation of extremely rapid rates of cooling. Amorphous metal wires have been produced by sputtering molten metal onto a spinning metal disk.<ref name=klement60>{{cite journal | last1=Klement | first1=W. Jr. |last2=Willens |first2=R.H. |last3=Duwez |first3=Pol |doi=10.1038/187869b0 |title=Non-crystalline Structure in Solidified Gold-Silicon Alloys |year=1960 |journal=Nature |volume=187 |issue=4740 |page=869| bibcode=1960Natur.187..869K |s2cid=4203025 }}</ref><ref name=lieb76>{{cite journal |last1=Liebermann |first1=H. |last2=Graham |first2=C. |doi=10.1109/TMAG.1976.1059201 |title=Production of Amorphous Alloy Ribbons and Effects of Apparatus Parameters on Ribbon Dimensions |journal=IEEE Transactions on Magnetics |year=1976 |volume=12 |issue=6 |page=921 |bibcode=1976ITM....12..921L}}</ref> | |||

| Several alloys have been produced in layers with thicknesses exceeding 1 millimetre. These are known as bulk metallic glasses (BMG). ] sells several ]-based BMGs. | |||

| Various surface treatment techniques, coatings, or ] may follow to improve the chemical durability (], ]), strength (], ], ]s), or optical properties (], ]). | |||

| Batches of amorphous steel have also been produced that demonstrate mechanical properties far exceeding those found in conventional steel alloys.<ref name=ponn04>{{cite journal |last1=Ponnambalam |first1=V. |last2=Poon |first2=S. Joseph |last3=Shiflet |first3=Gary J. |title=Fe-based bulk metallic glasses with diameter thickness larger than one centimeter |journal=Journal of Materials Research |year=2004 |volume=19 |issue=5 |page=1320 |doi=10.1557/JMR.2004.0176 |bibcode=2004JMatR..19.1320P|s2cid=138846816 }}</ref> | |||

| ===Glassmaking in the laboratory=== | |||

| Experimental evidence indicates that the system Al-Fe-Si may undergo a ''first-order transition'' to an amorphous form (dubbed "q-glass") on rapid cooling from the melt. ] (TEM) images indicate that q-glass nucleates from the melt as discrete particles with uniform spherical growth in all directions. While ] reveals the isotropic nature of q-glass, a ] barrier exists implying an interfacial discontinuity (or internal surface) between the glass and melt phases.<ref>{{cite web|url=http://www.metallurgy.nist.gov/techactv2004/TechnicalHighlights.html#glass|title=Metallurgy Division Publications|work=NIST Interagency Report 7127|url-status=live|archive-url=https://web.archive.org/web/20080916063500/http://www.metallurgy.nist.gov/techactv2004/TechnicalHighlights.html#glass|archive-date=16 September 2008}}</ref><ref>{{cite journal |last1=Mendelev |first1=M.I. |last2=Schmalian |first2=J. |last3=Wang |first3=C.Z. |last4=Morris |first4=J.R. |author5=K.M. Ho |doi=10.1103/PhysRevB.74.104206 |bibcode=2006PhRvB..74j4206M |title=Interface Mobility and the Liquid-Glass Transition in a One-Component System |year=2006 |journal=Physical Review B |volume=74 |issue=10|page=104206 |url=https://zenodo.org/record/1233751 }}</ref> | |||

| ] disposal at ].]] | |||

| ==== Polymers ==== | |||

| ].]] | |||

| Important ] glasses include amorphous and glassy pharmaceutical compounds. These are useful because the solubility of the compound is greatly increased when it is amorphous compared to the same crystalline composition. Many emerging pharmaceuticals are practically insoluble in their crystalline forms.<ref>{{cite web|url=http://www-ics.u-strasbg.fr/etsp//research/glass/field.php|archive-url=https://web.archive.org/web/20160525003628/http://www-ics.u-strasbg.fr/etsp/research/glass/field.php|url-status=dead|title=A main research field: Polymer glasses|archive-date=25 May 2016|website=www-ics.u-strasbg.fr}}</ref> Many polymer ]s familiar to everyday use are glasses. For many applications, like ] or ], polymer glasses (], ] or ]) are a lighter alternative to traditional glass.<ref name="Carraher-polymer">{{cite book|url=https://books.google.com/books?id=_izOBgAAQBAJ&q=polymer%20glass%20lighter%20alternative&pg=PA274|title=Introduction to Polymer Chemistry|first=Charles E. Jr.|last=Carraher|year=2012|pages=274|publisher=CRC Press|isbn=978-1-4665-5495-5}}</ref> | |||

| === Molecular liquids and molten salts === | |||

| New chemical glass compositions or new treatment techniques can be initially investigated in small-scale ] experiments. The raw materials for laboratory-scale glass melts are often different from those used in mass production because the cost factor has a low priority. In the laboratory mostly pure ] are used. Care must be taken that the raw materials have not reacted with moisture or other chemicals in the environment (such as ] oxides and hydroxides, ] oxides and hydroxides, or ]), or that the impurities are quantified (loss on ignition).<ref name=pnnl></ref> Evaporation losses during glass melting should be considered during the selection of the raw materials, e.g., sodium selenite may be preferred over easily evaporating ]. Also, more readily reacting raw materials may be preferred over relatively ] ones, such as ] over ]. Usually, the melts are carried out in platinum crucibles to reduce contamination from the crucible material. Glass ] is achieved by homogenizing the raw materials mixture (]), by stirring the melt, and by crushing and re-melting the first melt. The obtained glass is usually ] to prevent breakage during processing.<ref name=pnnl/><ref></ref> | |||

| Molecular liquids, ]s, ]s, and ]s are mixtures of different ] or ]s that do not form a covalent network but interact only through weak ]s or transient ]s. In a mixture of three or more ionic species of dissimilar size and shape, crystallization can be so difficult that the liquid can easily be supercooled into a glass.<ref>{{Cite book|page=21|chapter-url=https://books.google.com/books?id=-ajaBwAAQBAJ&pg=PA21|chapter=Crystals, Supercooled Liquids, and Glasses in Frozen Aqueous Solutions|first1=S.L.|last1=Ruby|first2=I.|last2=Pelah|title=Mössbauer Effect Methodology: Volume 6 Proceedings of the Sixth Symposium on Mössbauer Effect Methodology New York City, January 25, 1970|editor-last=Gruverman|editor-first=Irwin J.|year=2013|publisher=Springer Science & Business Media|isbn=978-1-4684-3159-9}}</ref><ref>{{Cite book|url=https://books.google.com/books?id=om31BwAAQBAJ&pg=PA226|title=Water Relationships in Foods: Advances in the 1980s and Trends for the 1990s|last1=Levine|first1=Harry|last2=Slade|first2=Louise|author-link2=Louise Slade|year=2013|publisher=Springer Science & Business Media|isbn=978-1-4899-0664-9|page=226}}</ref> Examples include LiCl:''R''H<sub>2</sub>O (a solution of ] salt and water molecules) in the composition range 4<''R''<8.<ref>{{Cite journal|vauthors=Dupuy J, Jal J, Prével B, Aouizerat-Elarby A, Chieux P, Dianoux AJ, Legrand J|s2cid=39468740|date=October 1992|title=Vibrational dynamics and structural relaxation in aqueous electrolyte solutions in the liquid, undercooled liquid and glassy states|journal=Journal de Physique IV |volume=2|issue=C2|pages=C2-179–C2-184|doi=10.1051/jp4:1992225|bibcode=1992JPhy4...2C.179D|url=https://hal.archives-ouvertes.fr/jpa-00251296/file/ajp-jp4199202C225.pdf |archive-url=https://web.archive.org/web/20200509082002/https://hal.archives-ouvertes.fr/jpa-00251296/file/ajp-jp4199202C225.pdf |archive-date=2020-05-09 |url-status=live}} European Workshop on Glasses and Gels.</ref> ],<ref>{{Cite book|url=https://books.google.com/books?id=uk66BAAAQBAJ&pg=PA38|title=Candy Bites: The Science of Sweets|last1=Hartel|first1=Richard W.|last2=Hartel|first2=AnnaKate|year=2014|page=38|publisher=Springer Science & Business Media|isbn=978-1-4614-9383-9}}</ref> or Ca<sub>0.4</sub>K<sub>0.6</sub>(NO<sub>3</sub>)<sub>1.4</sub>.<ref>{{cite journal|author=Charbel Tengroth|title=Structure of Ca0.4K0.6(NO3)1.4 from the glass to the liquid state|journal=Phys. Rev. B|volume=64|page=224207|year=2001|issue=22|doi=10.1103/PhysRevB.64.224207|bibcode=2001PhRvB..64v4207T}}</ref> Glass electrolytes in the form of Ba-doped Li-glass and Ba-doped Na-glass have been proposed as solutions to problems identified with organic liquid electrolytes used in modern lithium-ion battery cells.<ref>{{cite web|url=http://fortune.com/2017/03/05/lithium-ion-battery-goodenough/|title=Lithium-Ion Pioneer Introduces New Battery That's Three Times Better|website=Fortune|access-date=2017-05-06|url-status=live|archive-url=https://web.archive.org/web/20170409193506/http://fortune.com/2017/03/05/lithium-ion-battery-goodenough/|archive-date=9 April 2017}}</ref> | |||

| == Production == | |||

| See also: ], ] | |||

| {{Main|Glass production|Float glass|Glassblowing}} | |||

| ] | |||

| ] | |||

| Following the ] preparation and mixing, the raw materials are transported to the furnace. ] for ] is melted in ]s. Smaller-scale furnaces for speciality glasses include electric melters, pot furnaces, and day tanks.<ref name=ullmann /> | |||

| After melting, homogenization and ] (removal of bubbles), the glass is ]. This may be achieved manually by ], which involves gathering a mass of hot semi-molten glass, inflating it into a bubble using a hollow blowpipe, and forming it into the required shape by blowing, swinging, rolling, or moulding. While hot, the glass can be worked using hand tools, cut with shears, and additional parts such as handles or feet attached by welding.<ref name="Brittanica-glass-blowing">{{Britannica|235045|Glassblowing}}</ref> | |||

| ] for windows and similar applications is formed by the ] process, developed between 1953 and 1957 by Sir ] and Kenneth Bickerstaff of the UK's Pilkington Brothers, who created a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. The top surface of the glass is subjected to nitrogen under pressure to obtain a polished finish.<ref>{{cite web|url=http://www.pfg.co.za/about%20glass.htm |title=PFG Glass |publisher=Pfg.co.za |access-date=24 October 2009 |url-status=dead |archive-url=https://web.archive.org/web/20091106210357/http://www.pfg.co.za/about%20glass.htm |archive-date=6 November 2009}}</ref> ] for common bottles and jars is formed by ] methods.<ref>{{Cite book|url=https://books.google.com/books?id=Kbxv0oPJPK4C&pg=PA449|title=Code of Federal Regulations, Title 40,: Protection of Environment, Part 60 (Sections 60.1-end), Revised As of July 1, 2011|date=October 2011|publisher=Government Printing Office|isbn=978-0-16-088907-3}}</ref> This glass is often slightly modified chemically (with more alumina and calcium oxide) for greater water resistance.<ref>{{Cite book|url=https://books.google.com/books?id=Pwvtj9jJd6wC&pg=PA552|title=Leachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug Products|last1=Ball|first1=Douglas J.|last2=Norwood|first2=Daniel L.|last3=Stults|first3=Cheryl L. M.|last4=Nagao|first4=Lee M.|date=2012-01-24|publisher=John Wiley & Sons|isbn=978-0-470-17365-7|page=552|language=en}}</ref> | |||

| Once the desired form is obtained, glass is usually ] for the removal of stresses and to increase the glass's hardness and durability.<ref name="EB1911">{{Cite EB1911|wstitle=Glass|volume=12|pages=87–105}}</ref> Surface treatments, coatings or ] may follow to improve the chemical durability (], ]), strength (], ], ]s<ref>{{cite web|url= https://www.autoglassguru.com/blog/windshields-how-theyre-made/ |title= windshields how they are made|publisher=autoglassguru |access-date=2018-02-09}}</ref>), or optical properties (], ]).<ref>{{cite web|url=https://www.lehigh.edu/imi/teched/GlassProcess/Lectures/Lecture10_Pantano_Surface_Treatments.pdf |archive-url=https://web.archive.org/web/20150909081808/http://www.lehigh.edu/imi/teched/GlassProcess/Lectures/Lecture10_Pantano_Surface_Treatments.pdf |archive-date=2015-09-09 |url-status=live|title=Glass Surface Treatments: Commercial Processes Used in Glass Manufacture|last=Pantano|first=Carlo}}</ref> | |||

| ==Silica-free glasses== | |||

| Besides common ]-based glasses, many other ] and ] materials may also form glasses, including ] (e.g., ]), ], ], carbon dioxide (see below), ]s, ]s, ], ]s, germanates (glasses based on ]), tellurites (glasses based on TeO<sub>2</sub>), antimonates (glasses based on Sb<sub>2</sub>O<sub>3</sub>), arsenates (glasses based on As<sub>2</sub>O<sub>3</sub>), titanates (glasses based on TiO<sub>2</sub>), tantalates (glasses based on Ta<sub>2</sub>O<sub>5</sub>), ]s, ]s and many other substances.<ref name=vogel/> | |||

| New chemical glass compositions or new treatment techniques can be initially investigated in small-scale laboratory experiments. The raw materials for laboratory-scale glass melts are often different from those used in mass production because the cost factor has a low priority. In the laboratory mostly pure ]s are used. Care must be taken that the raw materials have not reacted with moisture or other chemicals in the environment (such as ] or ] oxides and hydroxides, or ]), or that the impurities are quantified (loss on ignition).<ref name="pnnl">{{cite web|url=http://depts.washington.edu/mti/1999/labs/glass_ceramics/mst_glass.html |title=Glass melting, Pacific Northwest National Laboratory |publisher=Depts.washington.edu |access-date=24 October 2009 |url-status=dead |archive-url=https://web.archive.org/web/20100505144629/http://depts.washington.edu/mti/1999/labs/glass_ceramics/mst_glass.html |archive-date=5 May 2010}}</ref> Evaporation losses during glass melting should be considered during the selection of the raw materials, e.g., ] may be preferred over easily evaporating ] (SeO<sub>2</sub>). Also, more readily reacting raw materials may be preferred over relatively ] ones, such as ] (Al(OH)<sub>3</sub>) over ] (Al<sub>2</sub>O<sub>3</sub>). Usually, the melts are carried out in platinum crucibles to reduce contamination from the crucible material. Glass ] is achieved by homogenizing the raw materials mixture (]), stirring the melt, and crushing and re-melting the first melt. The obtained glass is usually ] to prevent breakage during processing.<ref name=pnnl /><ref>{{cite web |last=Fluegel |first=Alexander |url=http://glassproperties.com/melting/ |title=Glass melting in the laboratory |publisher=Glassproperties.com |access-date=24 October 2009 |url-status=live |archive-url=https://web.archive.org/web/20090213120553/http://glassproperties.com/melting/ |archive-date=13 February 2009}}</ref> | |||

| Some glasses that do not include silica as a major constituent may have physico-chemical properties useful for their application in ] and other specialized technical applications. These include fluorozirconate, fluoroaluminate, ], ] and ]es. | |||

| === Colour === | |||

| Under extremes of pressure and temperature solids may exhibit large structural and physical changes which can lead to ] phase transitions.<ref>McMillan, P.F. Journal of Materials Chemistry, '''14''', 1506-1512 (2004)</ref> In 2006 Italian scientists created an amorphous phase of ] using extreme pressure. The substance was named ](a-CO<sub>2</sub>) and exhibits an atomic structure resembling that of Silica.<ref> 15 June 2006, www.newscientisttech.com. Retrieved 3 August 2006</ref> | |||

| {{Main|Glass coloring and color marking}} | |||